Glass-Fused-to-Steel (GFS) tanks, also known as Glass Lined Steel (GLS) tanks, represent a premium technology in the tank market. The fusion of glass and high-tensile mild steel combines the best properties of both materials. Steel provides strength and flexibility, while glass offers corrosion resistance.

This fusion eliminates the need for painting in the future, as the tank is inherently protected against corrosion by the glass enamel coat. One of the significant advantages of GFS tanks is the widening of the acceptable bracket of pH values after the fusion of steel with glass. This means that the tanks can withstand a wider range of pH levels without compromising their integrity.

Moreover, the application of Glass-Fused-to-Steel technology to both interior and exterior surfaces ensures that the tanks can withstand harsh environments for many years without encountering significant issues. This durability makes GFS tanks an excellent choice for various industrial, municipal, and agricultural applications where reliability and longevity are crucial factors.

GFS Tanks with Sealant: These tanks utilize a high-performance sealant to secure joints and seams, providing robust protection against leaks and corrosion.

The Design Standards followed for Glass-Fused-to-Steel (GFS) tanks –

Adhering to these standards ensures that GFS tanks meet the necessary safety, quality, and performance criteria required for water storage and fire protection applications. Compliance with AWWA D103-09 and FM 4020 standards also helps ensure consistency and interoperability in the design and construction of GFS tanks across different projects and locations.

A brief process of creating Glass-Fused-to-Steel (GFS) tanks involves several precise steps to ensure the quality and integrity of the finished product:

Here’s an overview of the typical quality check process –

A. Top-to-Bottom Assembly

B. Adding Rings & Accessories

C. Anchoring

1. Dome Roof – ZA / FBEC

2. Conical Roof – ZA / FBE / GFS

3. PVC Double membrane liner roof

4. GFS fixed leakproof roof

5. Geodesic Roof

Glass Fused Steel Sealant Tanks offer extensive applications across various application & industries. Some are mentioned below:

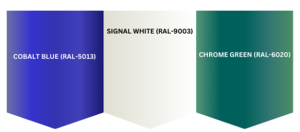

Rostfrei GFS tanks are available in three colour options.

Rostfrei Steels stands at the forefront as a premier manufacturer and trusted supplier of high-quality Storage Tanks, Storage Silos, and Material Handling Equipment. Expanding our innovative product range and service capabilities, we now also offer Pre-Fabricated Shed Buildings and Hot Dip Galvanizing Coating services through our newly established, state-of-the-art plant—delivering excellence you can depend on.

Rostfrei Steels is a head most manufacturer & supplier for Storage Tanks, Storage Silos & Material Handling Equipment.