Flat bottom silos are specifically engineered with a flat base, making them the perfect solution for permanent, high-volume, long term storage needs. The design incorporates advanced sweep augers, ensuring efficient material discharge and smooth operations even when handling large quantities of stored material. Rostfrei Grain Storage Silos are customised to perform in every Unique Challenging Condition, with primary focus to maintain grain quality.

Rostfrei operates a cutting-edge manufacturing facility spanning over 435,600 square feet. Equipped with CNC-based machinery, our facility processes 5,000 tonnes of steel each month, ensuring that your project timelines are easily met with Rostfrei’s full support.

Our range of this type of Silos in diameter from 9.14 Mtr with capacity 500 MT to 31.97 Mtr with capacity 15000 MT

Our range of this type of Silos in diameter from 3.65 Mtr with capacity 50 MT to 10.96 Mtr with capacity 750 MT

Our range of this type of Silos in diameter from 3.65 Mtr to 4.57 Mtr with varying capacities as per the requirements of our Clients.

In the manufacturing of Rostfrei silos, we exclusively

employ sheet metal with the cutting-edge Galvalume

(GI) and Zincalume (ZA).

with a gentle radius means more strength and better silo cleaning, improving materials unloading without any residue remaining so products are not contaminated.

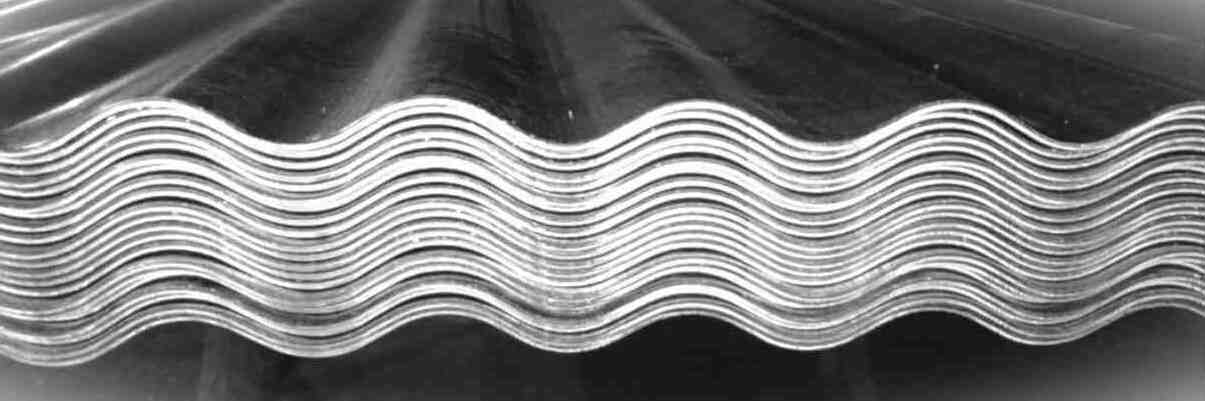

(Side walls) are processed on the dedicated CNC machine where profiling is being done so the sheets could withstand the load of the grain in the silos and pitch and depth of corrugations are considered to provide the better strength to the silos.

minimum on all our silos with hot dip galvanisation coating with minimum average coating thickness of 40 to 50 micron, depending upon the galvanisation standard.

are designed to store the grains, seeds and palletized products.

Rostfrei’s flat bottom silos are engineered to meet the highest international quality benchmarks, ensuring reliability and performance in every aspect. Our silos are designed in accordance with the following European standards

Flat bottom silos from Rostfrei are not just storage solutions; they represent a strategic investment for businesses aiming for efficiency, durability, and scalability. With the ability to meet global standards and adapt to various industrial needs, Rostfrei silos offer the ultimate solution to long-term storage challenges.

Our range of this type of Silos in diameter from 9.14 Mtr with capacity 500 MT to 31.97 Mtr with capacity 15000 MT

The process of creating Rostfrei’s flat bottom silos involves a series of precise steps, ensuring the highest quality and integrity of the final product:

In-Process Quality Check: Continuous monitoring during production to ensure adherence to specifications.

Internal Quality Check of Materials: Rigorous inspection of incoming materials to ensure they meet our high-quality standards.

Pre-Dispatch Inspection: A final comprehensive inspection before shipment to verify the quality and readiness of the product.

100 mm raised platform step

Anchoring PCD

Silo dia starts 50 mm away from raised step this gap is filled via RCC & foundation sealant Coping

Rostfrei Steels Make Flat Bottom Silos are the most Innovation Storage Solutions for all type of Grains, Oilseeds, Pulses, Millets and other cash crops.

Ranging from volume 60 CuM (dia- 4.57 m, height – 4.44 m) to 20,060 cuM( dia- 33.80 m, height-28.60 meters) ,Rostfrei Silos are Designed and manufactured in accordance with American Standard ANSI / ASAE Standards or European Standard EN 1993-4-1

Rostfrei Steels Silos have scientifically calculated Aeration & Ventilation System, Precise Condition monitoring System, Effective Fumigation System, and Appropriate MOC ( Zincalume / Galvanized / Magnelis) for Safe storage of grains throughout all seasons, especially during hot & humid climates

ROSTFREI STEELS silos are designed adhering to International Standard on Precision CNC based machine, Utilizing Raw Materials from Topmost manufacturers – following Exhaustive Quality checks after every consecutive manufacturing process

Rostfrei Silos reduce Operations & Maintenance cost required for Quality storage of grains by Innovations in Material of consumption, Anti-Condensation unit, Precision Condition monitoring system and Corrosion protection measures

Minimum Maintenance , Cost-effective & Prompt after-sales Service ensures that you focus only on improving milling efficiency and Business Gains

Note: We serve most of the Asian regions and have successfully installed Flat Bottom Silo in Dubai, Africa, Sri Lanka, Nepal, Bangladesh, Bhutan, Vietnam, Myanmar, Cambodia, Thailand, Kuwait, Bahrain, Qatar, Saudi Arabia, etc.

1. Dome Cap at center is first mounted after verifying

foundation works completion & verification

2. First wall Rings are assembled along with Rafters of roof

Each of the wall sheets are overlapped by 150-200 mm at vertical joints, sealed via Butyle seal tape and joined via 8.8 grade HDG (500 GSM) Hight tensile Nut Bolts with rubber washer & Gl washer from either sides. Each of wall sheet is horizontally overlapped 70 mm and sealed via Silicon Sealant (From inside of Silos) and joined via HT Nut bolt galvanized 550 GSM with Rubber washer & Gl washer from either sides

ROOF RAFTERS TO BE ASSEMBLED WITH

TOPMOST RING OF SILO

ROOF RAFTERS WITH DOME CAP ASSEMBLED WITH

TOPMOST RING (1ST RING OF SILO)

ROOF SHEETS ARE OVERLAPPED WITH EACH OTHER BY 200 MM AND NUT-BOLTING (8.8 GRADE HIGH TENSILE HDG) ALONG WITH RUBBER WASHER AND GI WASHER

GOOSE NECK VENTS OVER THE ROOF ARE ASSEMBLED OVER ROOF VIA NUT-BOLTING WITH RUBBER & GI WASHERS, AND SEALING IS DONE USING ANABOND SEAL TAPE & PU SEALANT (SIKAFLEX TS PLUS MAKE). Ladders, Railings are fixed over roof. PU FOAM SEALANT IS APPLIED AT TOP SECTION AND NEAR DOME CAP. VERTICAL JACKS FIXEDINSTALLED FOR LIFTING SILOS VERTICALLY UP

Pressurized water spray testing is done over at every nut-bolt assembly of sheet overlapping, stiffners fix, roof sheets to test integrity of the structure. Once this test is passed, assembly is lifted up via Vertical jacks to add consecutive Rings of wall sheets

Pressurized water spray testing shows the integrity of the workmanship and once it is done, Structure is lifted up for further addition

Goal post (Support for overhead conveyor structure), Wind Rings (Hollow HDG 350GSM metallic pipe of 50 mm), Stiffeners (HDG 550 GSM) etc. are added along with additional wall sheets by simultaneous lifting by vertical jacks

After adding additional two rings to the structure along with other steel parts like wind rings, stiffeners etc., pressurized water spray test is done again for whole structure

Whole Structure is built like this, and there after ancillary equipment’s if any, are added

J Bolts grouted over Base plate are placed over Anchoring PCD pockets. The pockets are then filled with RCC cement with waterproofing solution, and this civil coping is done all around silos

With over 8,000 successful installations, our project team is equipped to professionally handle and commission any silo project, even in the most challenging environments, all while adhering to strict timelines.

The silos are meticulously assembled using high-quality sealants and high-tensile bolts. Hydro-testing is performed after the completion of the roof segment and each subsequent ring to ensure optimal performance and safety.

To ensure the longevity and efficiency of the silo, our on-site project team provides comprehensive training to the client’s team. This training is designed to promote cost-effective operation and maintenance, ensuring that the silo performs at its best throughout its lifespan.

⦁ Grain Processing Industries: Flour Mill, Rice Mills, Pulses Mills, Oats Processing, Millet Processing

⦁ Solvent Industries- Edible Oil manufacturing facilities for Soya, sesame, mustard, Castor etc.

⦁ Animal Feed Industries – Poultry Feed & Cattle feed

⦁ Grain-Based Distillery

⦁ Starch Industry

⦁ Large Scale Storage Facility Management- Food Corporation of India, NCML, CWC etc.

Our in-house design team, equipped with the latest design software and tools, creates silos to international standards. This ensures exceptionally durable silos with a design life of over 40 years. Part detailing is done using advanced 3D software for utmost precision.

We utilize imported machinery from the US and Europe for turret punching and laser cutting. CNC-based operations guarantee the accuracy of every component, ensuring hassle-free installation and zero maintenance or repairs after installation.

Rostfrei Silos are designed not only to store grains effectively but also to maintain their quality throughout all seasons. We go the extra mile by offering customized steel grades, condition monitoring accessories like temperature monitoring and controlling, and a user-friendly operational interface. Crucial operations are automated to preserve grain quality, regardless of operator error.

With an extensive network of service engineers across the country, we ensure prompt after-sales service within 48 hours of a client’s request anywhere in India. This guarantees long-term, hassle-free operation.

A single unit of Rostfrei’s Flat Bottom Silo can store 15,000 metric tons of grain, offering exceptional capacity for large-scale storage.

Rostfrei Steel Silos are constructed from high-grade steel with protective coatings and additional corrosion-resistant measures. Every silo undergoes rigorous design life tests, including Finite Element Analysis (FEA) and load analysis, to ensure it performs optimally at the installation site.

Each Rostfrei Silo is fully customizable, from dimensions and material of construction (MOC) to accessories and design parameters, ensuring that all project’s unique requirements are met.

Grain storage silos play a crucial role in ensuring food security and maintaining the quality of harvested grains. By storing grains in a controlled environment, silos protect crops from weather, pests, and other contaminants, minimizing losses and enhancing food availability throughout the year.

Efficient Space Utilization: : Silos are designed to store large quantities of grain in a relatively small footprint, making them ideal for maximizing storage efficiency.

Controlled Environment: With proper ventilation and temperature control, silos help preserve grain quality by reducing the risk of spoilage.

Cost-Effective: : Wall panels are profiled and curved using CNC corrugation machines, ensuring uniformity and strength.

Automation: Fabricated parts undergo hot-dip galvanizing with a coating of over 500 GSM to enhance durability and corrosion resistance.

Sustainability: Throughout the production process, multiple quality checks are conducted to ensure the highest standards:

For any organization involved in agriculture, investing in grain storage silos is a strategic decision to ensure long-term profitability and efficiency.

Rostfrei Steels stands at the forefront as a premier manufacturer and trusted supplier of high-quality Storage Tanks, Storage Silos, and Material Handling Equipment. Expanding our innovative product range and service capabilities, we now also offer Pre-Fabricated Shed Buildings and Hot Dip Galvanizing Coating services through our newly established, state-of-the-art plant—delivering excellence you can depend on.

Rostfrei Steels is a head most manufacturer & supplier for Storage Tanks, Storage Silos & Material Handling Equipment.